Die CONiQ® Cloud ist die IoT-Grundlage, um Ihre Maschinen und Prozesse intelligenter zu machen.

Die CONiQ Cloud wurde entwickelt, um Daten direkt von Ihren Maschinen abzurufen. Sie bietet verschiedene Vorteile von einfacher Zustandsüberwachung und erhöhter Transparenz bis hin zur Unterstützung durch Ad-hoc Service-Experten im Falle prozesskritischer Ereignisse. Die CONiQ® Cloud verfügt über ein benutzerfreundliches Dashboard, welches KPIs direkt auf Ihrem mobilen Endgerät anzeigt. So haben Sie alle relevanten Informationen jederzeit und überall auf Abruf verfügbar. Das globale Setup ermöglicht es, Hilfen für die Dateninterpretation, individuelle Handlungsempfehlungen und Optimierungen schnell und einfach zu erhalten – unser Service ist nur einen Klick entfernt. Basierend auf Ihren Maschinendaten erhalten Sie umfangreichen Service auf allen Ebenen und unterstützen dadurch Ihr Betriebs- und Wartungsteam.

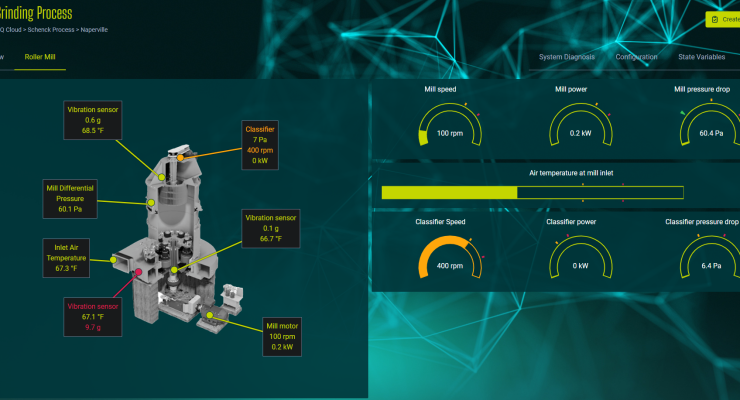

CLOUD-DASHBOARD

CONiQ® Cloud verfügt über ein benutzerfreundliches Web-Dashboard, über welches KPIs direkt auf jeden Laptop, Tablet oder Mobiltelefon abgerufen werden können. Der Zugriff ist überall dort möglich, wo eine Internetverbindung vorhanden ist. Jedes Dashboard ist mit ausgewählten Nutzerkonten verknüpft, sodass diese nur auf zugeordnete Maschinen zugreifen können.

HAUPTMERKMALE:

- Schnelle Übersicht über den Zustand aller Ihrer Maschinen.

- Detaillierte Zustandsübersicht ausgewählter Maschinen.

- Fokus auf schnell-ladenden Dashboards.

- Responsive Webdesign: Dashboard-Panel passen sich automatisch der Bildschirmauflösung an und Panel Interaktionen wie das Zoomen funktionieren reibungslos mit Maus und Berührung.

- Zeitzone und Dashboard-Sprache passen sich automatisch an das Client-System an.

- Die grafische Darstellung von Schwellenwerten in Trenddiagrammen ermöglicht eine schnelle Beurteilung, ob eine Maschine innerhalb oder außerhalb ihrer Toleranzbereiche arbeitet.

- Konfigurierbare E-Mail-Warnungen bei Überschreitung des Schwellenwerts.

CONIQ® CLOUD SERVICE –

SMARTES ABWEICHUNGS-MONITORING

FÜR ALLE, DIE MEHR ERWARTEN: UNVORHERSEHBAR WAR GESTERN.

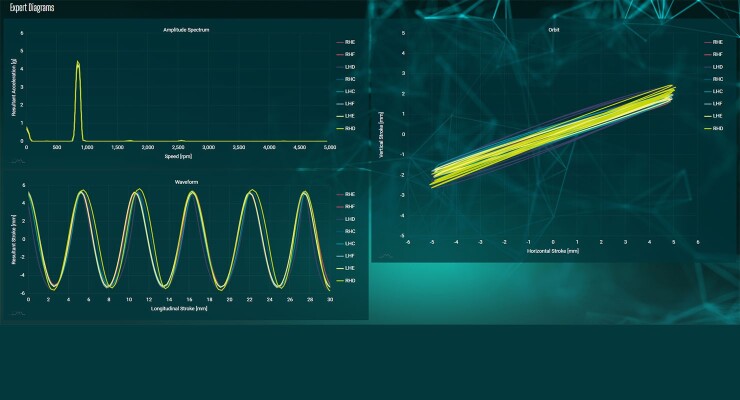

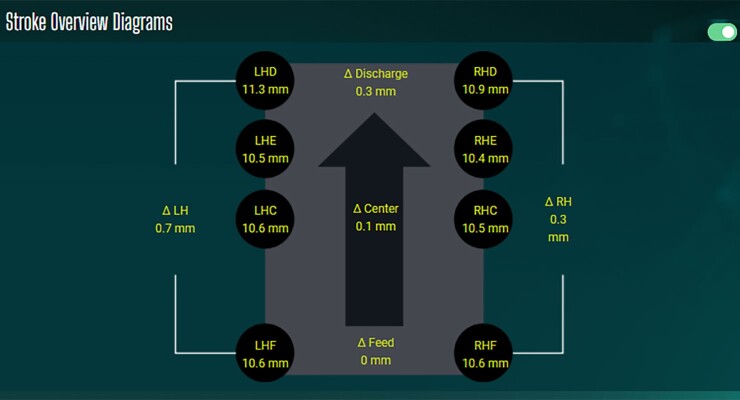

Wir geben Ihnen mehr Zeit zum Reagieren – mit dem CONiQ® Cloud Service. Der smarte digitale Service erkennt jede Abweichung vom Normalbetrieb deutlich früher als je zuvor und geht damit weit über klassische Warnmeldungen hinaus. Er kombiniert neueste Machine-Learning-Technologien mit Expertenwissen zu Maschinen und Prozessen. Produktspezifische Dashboards sorgen für einen schnellen Überblick. Zusammen mit Frühwarnindikatoren und dem Zugriff auf eine umfassende Störungsmusterdatenbank, mit schnellen Korrekturmaßnahmen ermöglicht der CONiQ® Cloud Service Abweichungs-Monitoring mit Weitblick.

EIN SERVICE DER MEHR BIETET ALS DIE SUMME SEINER KOMPONENTEN

Unser Service umfasst ein datengesteuertes Modell, das das normale Verhalten auf der Grundlage gesammelter Daten und des aktuellen Maschinen- und Prozessbetriebs vorhersagt. Entscheidend neu ist dabei der Umgang mit den Unterschieden zwischen gemessenen und vorhergesagten Werten: Daraus wird der Grad der Abweichung vom Normalbetrieb abgeleitet. Die Machine-Learning-Algorithmen überwachen nicht nur einzelne Werte, sondern die Korrelation sämtlicher Werte, insbesondere im Hinblick auf den Betriebsmodus, in dem sich die Maschine oder der Prozess gerade befindet.

HÖCHST SENSIBEL BEI JEDER VERÄNDERUNG

Der CONiQ® Cloud Service ermöglicht es Ihnen, Abweichungen vom normalen Maschinen- und Prozessbetrieb zu erkennen, lange bevor herkömmliche Alarmgrenzen ausgelöst werden. Durch die Erfassung und Auswertung von Daten aus dem Gesamtbetrieb, wie z.B. Vibration, Geschwindigkeit, Druck, Temperatur u.v.m., kann der Service wichtige Messwerte überwachen, um zu verhindern, dass Menschen oder Maschinen zu Schaden kommen.

HALTEN SIE IHREN BETRIEB JEDERZEIT SICHER.

Nutzen Sie unseren neuesten digitalen Service ganz einfach, um Sicherheit und effizienten Betrieb zu erreichen: Verlängern Sie Ihre Reaktionszeit für notwendige Maßnahmen – lange bevor Defekte zu einem Problem werden können.

VORTEILE:

- Bis zu 10-mal schnellere Reaktionszeit

- Erfassung der gesamten Prozessdaten einschließlich mechanischer Schwingungen, Geschwindigkeit, Druck, Temperatur und vielem mehr

- Korrelation sämtlicher Werte mithilfe von Künstlicher Intelligenz (Machine Learning)

- Maschinen-spezifische Dashboards für größtmögliche Transparenz

- Zugriff auf eine Datenbank mit umfassenden Beschreibungen zu Störungen und Defekten für schnelle Korrekturmaßnahmen

- Anwendbar auf alle Arten von Maschinen und Prozessen

DATA SOURCES

CONiQ Cloud® ermöglicht die Datenverarbeitung aus verschiedenen Quellen. Es kann mit jedem Kundensystem oder jeder anderen IoT-Cloud verbunden werden. Mit der Veröffentlichung der CONiQ Cloud bieten wir unsere eigene IoT-Edge-Lösung CONiQ Monitor an.