ProDV® Dome Valves, part of our Clyde Process range – are proudly the original and most reliant

The operating efficiency of many material handling systems rely upon the original and world’s best ProDV® Dome Valve (also available as a Spheri Valve), currently installed in over 10,000 applications worldwide. Simple in design and low in maintenance, this high performance valve is used throughout a wide range of industries.

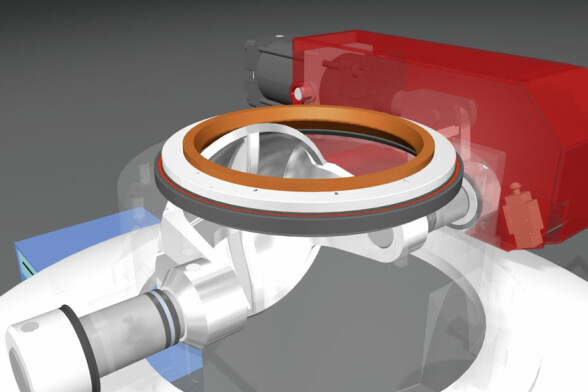

In action, the Schenck Process ProDV® Dome Valve is a pressure tight compressed air operated valve, capable of returning over one million maintenance-free cycles, even in abrasive, hazardous or toxic applications. The fast-closing cut-off valve incorporates a unique inflatable sealing mechanism. This provides the pressure tight seal, against the dome surface when in the closed position – ensuring reliable, instant control and efficient performance.

As the first Dome Valve launched to the market, its success and reputation has evolved it into it becoming a critical part of an overall production process. Consequently, over time, other manufacturers have created adaptations of the original Dome Valve, as value-engineered, non-commodity alternatives. Thereby potentially impacting quality output and performance. Which is why Schenck Process are very proud of the long-standing integrity of the ProDV®.

As the original Dome Valve, the ProDV® features include:

- The original and most reliant Dome Valve

- Cuts through moving or static material

- Full bore material flow

- Only a quarter turn from fully closed to fully open

- Air tight seal, when closed

- Dependable, fast closing performance

- Simple maintenance, long-life performance

- Designs can be provided for pressures up to 35 bar. 10 bar as standard

- Can handle material temperatures up to 480 ºC

- Handles abrasive, toxic, hazardous, friable and cohesive products with ease

- No moving wear parts

Typical materials handled:

- Detergents

- Minerals

- Ores

- Chemicals

- Ash

- Granules

- Powders

The Schenck Process ProDV® is ATEX Compliant.

Totally unrestricted full bore material flow is assured through the unique design of the ‘dome’ assembly. A mere quarter turn is sufficient to move from the fully closed to the fully open position. This action positions the dome completely clear of the material flow path.

From Fine Abrasive Powders to cohesive Materials user options extend to the choice of ‘Dome’, both in terms of raw material and any surface coatings required.

The Dome is usually produced from Cast Iron, S G Iron or Stainless Steel, but other materials and designs will be considered by application.

From Foodstuffs to High Temperature Ash a range of inflatable seals are available, depending upon the application. The choice includes a white food grade seal as well as those specially formulated for high temperatures or other hostile applications. Moving and Static Column Cut Off All Spheri Valves / Dome Valves are capable of handling fine grain materials and hard abrasive products.

Vane Actuator Models can cut through static columns of material up to 2mm particle size. They can also cut through moving columns of powders, pastes and granular products similar to coal above 2mm. Cylinder Actuator models have the added capability of being able to cut through static columns of material above 2mm.

Videos

We’re there for you

Partnership for us means always being on hand to support you whenever and wherever you need us. With our global network of locations and expert partners, we make sure we are always right by your side.