Every second counts when you’re processing pig iron – which is why fully automatic in-motion weighing is the ideal solution for torpedo wagons. The high-precision MULTIRAIL® HotMetalWeight train scales developed by Schenck Process enable you to weigh pig iron as it travels from the steel plant to the blast furnace. You don’t waste any time as it’s fully automatic and doesn’t require a scales operator.

Precise force measuring technology for process optimization

The measured pig iron production weight can then be balanced according to the shift, daily and monthly total. This data serves as a basis for the performance record for the blast furnace plant. Because the information about the actual weight is also available before the supply of pig iron reaches the steel plant, subsequent processes on the converter can also be optimized.

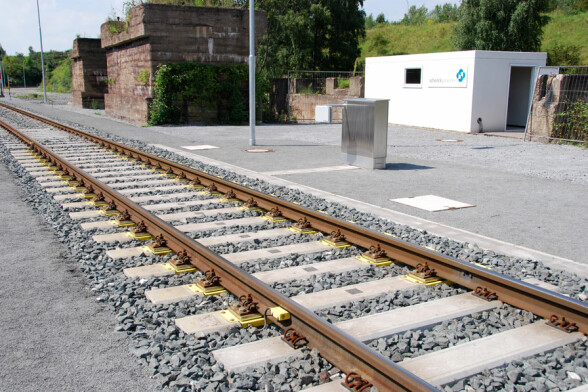

The precise force measuring technology under the rails weighs the actual weights of all laden and empty wagons as the vehicle passes over. Special force sensors integrated in the standard concrete sleepers safely transfer the forces and torque affecting the track to the track bed and at the same time record the wagon weight with a high level of accuracy and reproducibility.

The system also detects the wagon numbers and registers all values. Only the static function of the scales is used for adjustment; the customer does not need to provide reference scales.

Structure and integration. Without wasting time

The scales are integrated without the need for foundations by simply laying the weighing concrete sleepers. The rails are then welded without gaps. The weighing system can therefore be installed in the roadbed during regular track overhaul without wasting time.

The weighing values and the other process data is processed with the help of the Windows-based software DISOWARE Terra.

Downloads

Data sheets

Brochures

Videos

We’re there for you

Partnership for us means always being on hand to support you whenever and wherever you need us. With our global network of locations and expert partners, we make sure we are always right by your side.

Schenck Process - your partner worldwide

With an unrivaled global network of operating companies and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and well-engineered measuring technology for weighing, feeding, conveying, automation and air filtration.