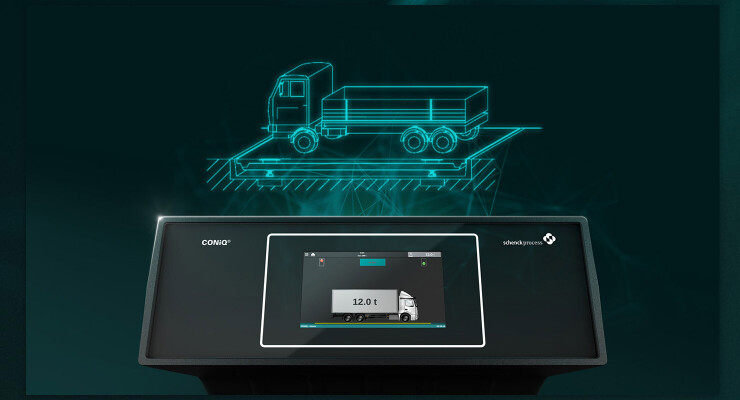

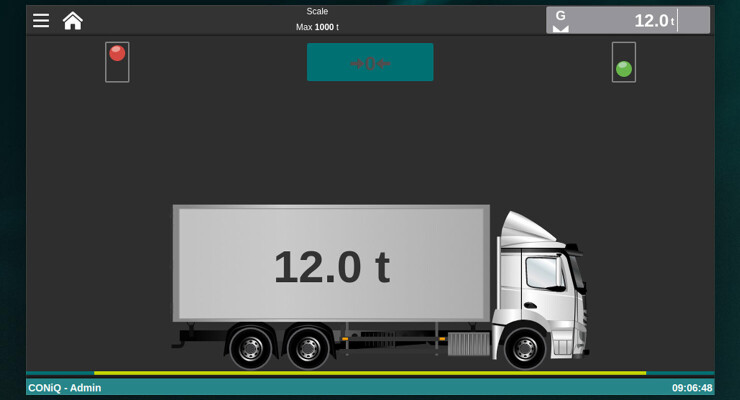

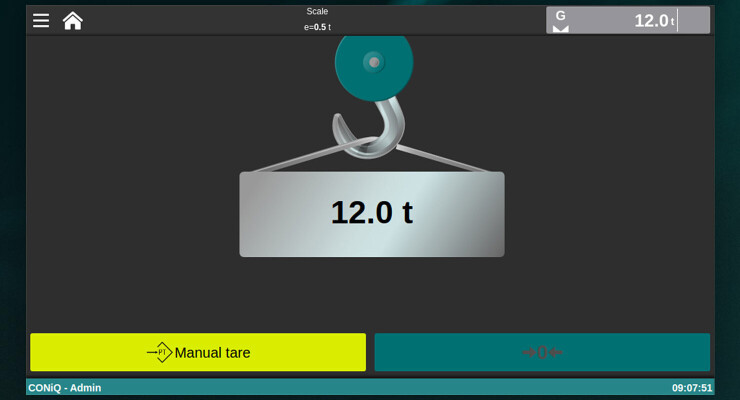

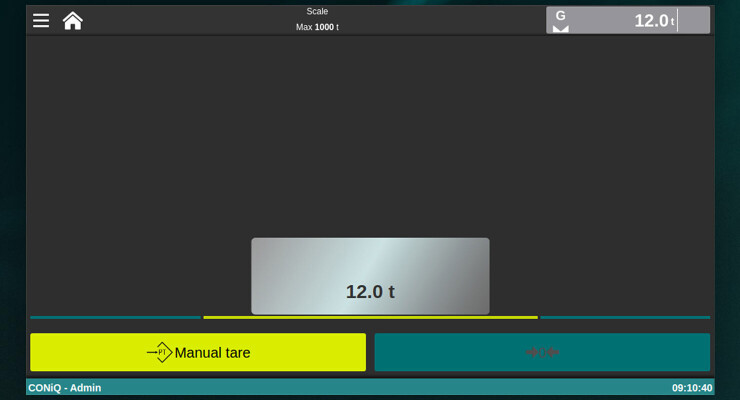

The touch interface guides the user intuitively through all weighing operations and process controls. Individually definable user groups and very short learning curves ensure the highest flexibility and efficient working. Integral plain text fault descriptions help users diagnose issues quickly and simply.

Controller access can be by Ethernet or WiFi. The web-based user interface enables fast service access without requiring additional software installation. This makes downtimes much shorter. CONiQ® Control can also be conveniently controlled from mobile devices.

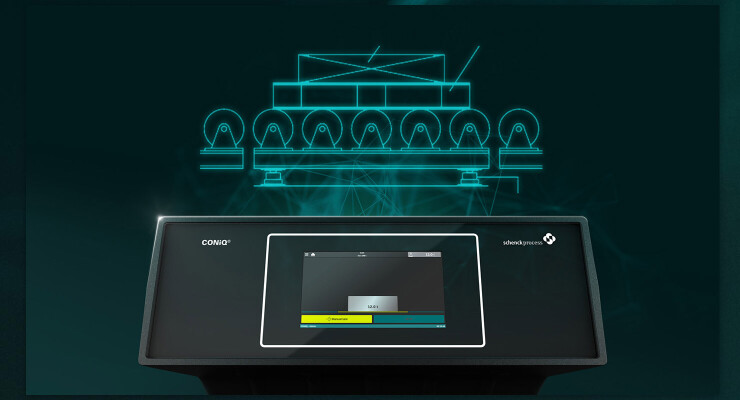

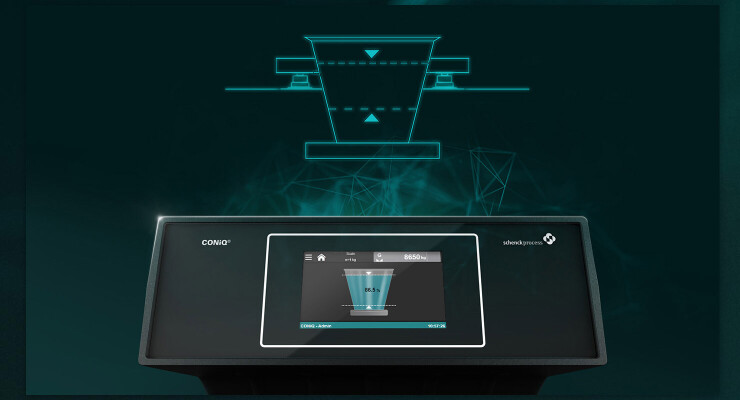

Maximum flexibility through all-modular design. Both the hardware and the software can be adapted to their environments and applications. The control functioning is defined by the software, the expansion modules that are added, and the parameter settings. Continuous development of further innovative functional modules ensures steadily expanding application areas. CONiQ® Control has a colour TFT touch display, optional WiFi and is available in several different housing versions.

CONiQ® Control has three freely assignable slots for I/O expansion modules, a field bus interface for simple system integration, and two USB connections for other peripherals. All this enables flexible adaptation to individual requirements. The internal PLC allows to implement automation tasks and extensions of the standard applications and to integrate custom visualizations.

CONiQ® Control has legal-for-trade to EN 45505, OIML R51 and NTEP. No re-verification is necessary following replacement of the mainboard or I/O modules. The controller is certified according to CE, UKCA and EAC. More to follow.