The CONiQ® Cloud is the IoT backbone to make your machines and processes smarter.

CONiQ Cloud is designed for you to access data from your assets and offers various benefits from simple monitoring and transparency to ad-hoc service expert support on immediate and historic machine issues. In addition, the CONiQ® Cloud includes easy-to-use dashboards with KPI information directly on your mobile device, so you have all relevant information with you - any time, any place. Thanks to the global setup, your need for support on data interpretation, recommendation for action and constant improvement is just one click away. Thus, you can get complementary support on all levels around the data of your assets to support your operation and maintenance team.

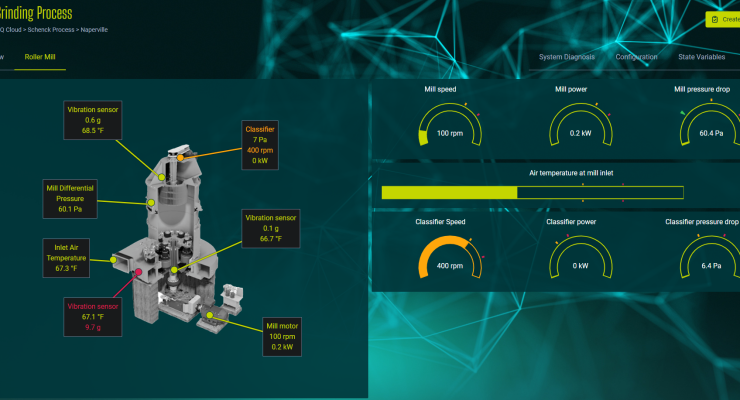

CLOUD DASHBOARD

CONiQ® Cloud includes an easy-to-use Web-Dashboard which brings KPIs directly to any laptop, tablet or mobile phone with internet connection. Dashboards are linked to specific accounts, so that users get access to their private machines only.

KEY FEATURES:

- Fast overview of all your machines condition.

- Detailed view of the condition of a single selected machine.

- Focus on fast dashboard loading.

- Responsive Webdesign – Dashboard panels adapt to screen resolution and panel interactions such as zooming work smoothly with both mouse and touch.

- Time zone and dashboard language automatically adapt to the client system.

- Graphical illustration of thresholds in trend diagrams enable quick assessment of whether a machine is operating within or outside its tolerance bands.

- Configurable E-Mail alerts on threshold exceedance.

CONIQ® CLOUD SERVICE –

SMART DEVIATION MONITORING

Time to expect more. Unpredictable is over.

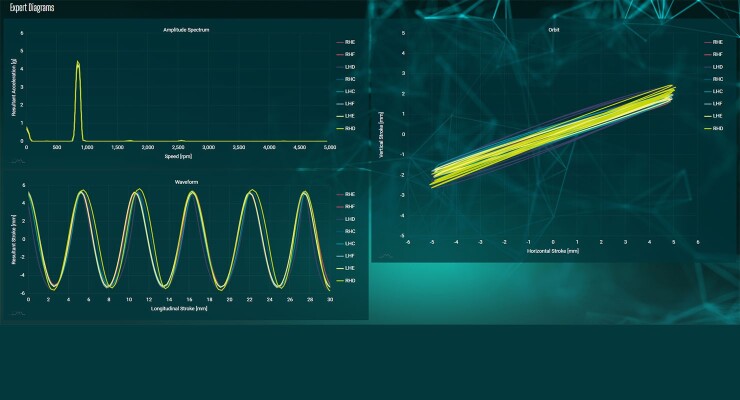

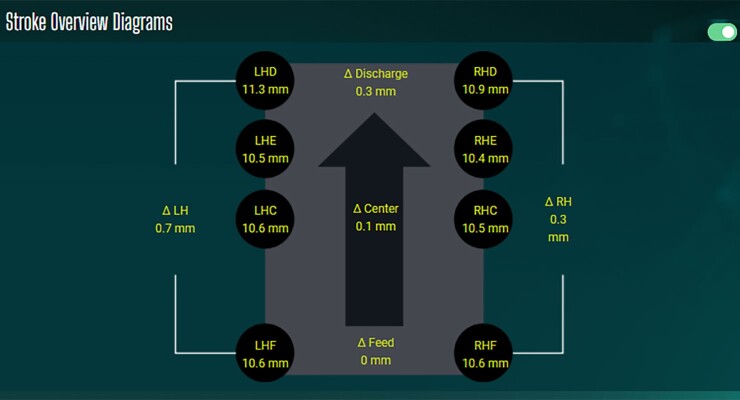

We give you more time to react – with CONiQ® Cloud Service. The smart digital service detects any kind of deviation from normal operation significantly earlier than ever before, going far beyond classic alarms. It combines latest machine learning technologies with deep machine and process knowledge, providing specific dashboards, early warning indicators, and access to the fleetwide failure pattern database for fast corrective action.

A SERVICE THAT IS GREATER THAN THE SUM OF ITS PARTS

Our service comprises a data driven model, predicting normal behavior based on historical data and current machine and process operation. Its decisively new feature is how it handles the difference between measured and predicted values, reflecting the degree of deviation from normal operation. The machine learning algorithms do not merely monitor single values, but the correlation of all values, especially regarding the operation mode the machine or process is currently in at any given time.

MORE SENSITIVE TO ANY KIND OF CHANGES

CONiQ® Cloud Service enables you to identify deviation from normal machine and process operation long before traditional alarm limits go off. Gathering and assessing data from the overall operation, such as vibration, speed, pressure, temperature, and many more, the service monitors important measurements to prevent people from getting harmed and machines from getting damaged.

Keep your operation safe at all times.

It’s easy to use our latest digital service to provide safety and security for efficient operations by extending your response time for taking appropriate actions – long before outages become a problem.

BENEFITS:

- Up to 10 times quicker response/reaction time

- Capture the overall process data including vibration, speed, pressure, temperature, and many more

- Correlation of all values by means of Artificial Intelligence (machine learning)

- Machine-specific dashboards for maximum transparency

- Access to the fleetwide failure pattern database for fast corrective action

- Applicable for any type of machine and process

DATA SOURCES

CONiQ Cloud® enables data-processing from various sources. It is connectible to any customer system or other IoT Cloud. With the release of CONiQ Cloud, Schenck Process offers a proprietary IoT edge solution CONiQ Monitor.