Direct weighing technology – for accurate weighing results with minimum effort.

Schenck Process, the global market leader in measuring and process technology solutions, is proud to announce the latest generation of its SENSiQ® WB weighbeam technology.

For more than 30 years Schenck Process weighbeams, now all branded SENSiQ® WB, have been the standard for tough weighing tasks, especially in the heavy duty and harsh environment of steel production.

The latest release from Schenck Process is the world’s highest capacity loadcell with a nominal capacity of 600 metric tonnes for installation by simple bolting into the given steel structure. This makes it ideal for hopper scales with a total weight of up to 2,500 tonnes as well as for hoppers in train loading systems.

Furthermore, the latest SENSiQ® WB development is characterized by the following improved technical features:- expanded operating temperature range between -40° C and 180° C

- high accuracy, which has always been a key benefit of the SENSiQ® loadcell generation, has been further improved to an error of +0.07% across the entire load range

- all loadcells of the SENSiQ® WB fulfil IP68 requirements according to ANSI/IEC 60529.

Schenck Process customers love the simple and cost-effective installation of these SENSiQ® WB weighbeams. They connect directly inside the given structure without moving parts and transmit all disturbance forces and moments with minimal measuring value interference. Plus, SENSiQ® WB weighbeams function entirely maintenance-free in the harshest conditions, offering high long-term stability and high reproducibility.

Typical applications are ladle turret, ladle transfer car, scrap basket, roller table and tundish car scales as well as silo and hopper weighers.

The full SENSiQ® WB range now includes 11,5 t, 15 t, 25 t, 40 t, 50 t, 100 t, 150 t, 200 t and 600 t rated capacity types.

About Schenck Process

Schenck Process is the global technology and market leader in applied measuring technology. We make processes work in all areas of industry throughout the world. For us that means improving our customer processes in terms of reliability, efficiency, and accuracy. Combining outstanding equipment and extensive process knowledge, we develop and manufacture innovative solutions for weighing, feeding, conveying, screening, automation, and air filtration applications. We focus on the needs of our customers and support them through the whole lifecycle of a product. For more information, visit schenckprocess.com

Pressebilder

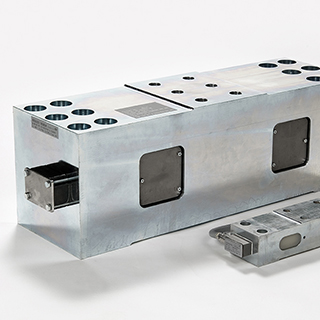

Pressefoto: SENSiQ WB weigbeam 25t | 600t herunterladen

Unsere Experten sind überall für Sie da

Gute Partnerschaft bedeutet für uns: Wir stehen Ihnen zur Seite, wenn Sie uns brauchen. Mit unserem globalen Standortnetzwerk sind wir jederzeit für Sie da.

Schenck Process - Ihr weltweiter Partner

Mit einem globalen Netzwerk aus operativen und kompetenten Partnern steht der Name Schenck Process weltweit für erstklassige Prozesslösungen und ausgereifte Messtechnik in der Wäge-, Dosier-, Förder-, Automatisierungs- und Luftfiltrationstechnik.