Efficient processes and optimized resource planning are indispensable for smooth logistics operations. To achieve this, the automation and standardization of repetitive processes are key. Our LOGiQ logistics solution has been specially developed to help you automate and optimize your yard management processes and increase your overall productivity.

Yard Management Software for Automation with LOGiQ

Complete transparency and control

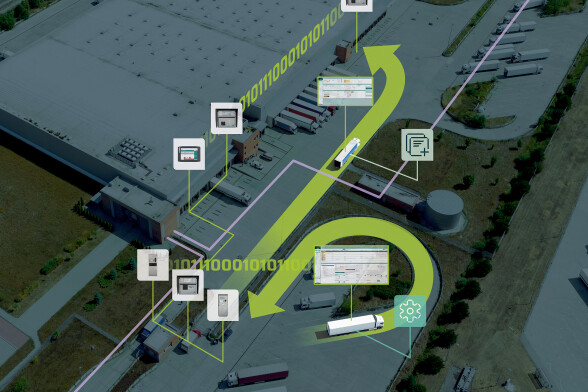

LOGiQ automates the entire end-to-end shipping process on your premises for smooth loading and unloading operations, seven days a week, 24 hours a day. Whether it's by road, water, or rail, this smart solution takes care of every individual step in the process, from order to delivery, autonomous and precise loading of transport vehicles, control of the flow of goods, and comprehensive documentation of all processes.

Thanks to seamless integration into existing systems and processes, LOGiQ provides you with a continuous flow of data. The web-based interface also ensures that this data is available to you in real-time, no matter where you are. This gives you the necessary transparency to continuously optimize and enhance operations on your premises.

Your partner for fully automated yard processes

You are already using our weighing technology and are looking for the NEXT? Then discover how our LOGiQ yard management can take you to the next level.

Benefits for logistics managers:

- Short processing times through efficient resource utilization and planning along the logistics chain

- High-quality assurance through controlled weighing automation

- Seamless real-time data flow due to the seamless integration with existing systems

- 24/7 availability thanks to the web-based interface

Benefits for drivers and loading personnel:

- 24/7 self-service

- No waiting times or congestion

- Controlled loading and unloading process

- Intuitive operation of LOGiQ terminals

- No language barriers - terminals with over 20 different language options

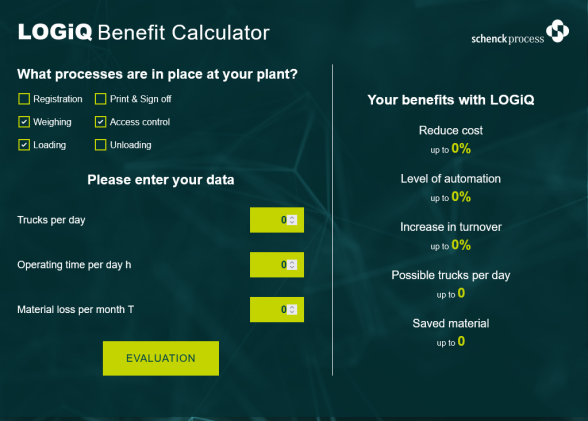

Discover your individual optimization potential!

No matter which logistics processes you want to optimize or automate on your premises, LOGiQ is the choice for your individual needs. Discover improvement potential on your side today.

A versatile solution for various industries

LOGiQ is a proven solution in a wide range of industries. Whether you operate a cement or chemical plant, own a paper mill, or are involved in the waste disposal industry, our experts will work with you to find the perfect way to automate and optimize your dispatch processes. The system is flexible and can adapt to your needs and size, allowing for easy expansion and scalability when required.