Schenck Process has designed pneumatic injection solutions across many industries and has consistently improved productivity rates, system reliability, availability, and performance. RotoFeed carbon and lime injection controls the feed rate with variable frequency drive and fixes the injection line airflow, avoiding variable material flow and reducing plugging.

Wherever there is a need to inject powdered or granular materials, into a process environment, there is a potential application for Schenck Process injection technology. Products can be continuously injected into process environments at smooth, easily controlled rates, with accuracies ±0.5% and against back pressures of 20 barg or more.

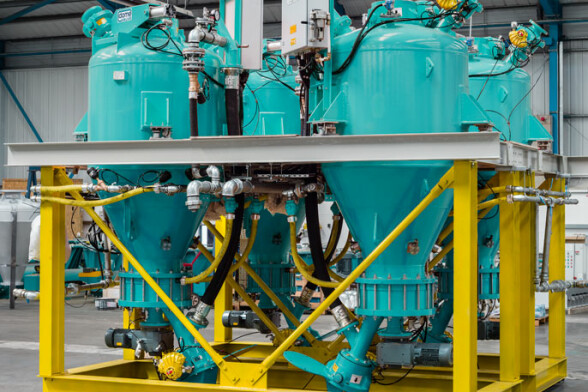

The RotoFeed machine consists of two pressure vessels, a rotating volumetric feeder at the outlet and valves to control the air supply, material flow and vessel pressure. The dispensing vessel is used to provide a constant supply of material to the volumetric feeder. When the material is injected, the dispensing vessel will be pressurized. The lock vessel is used to periodically replenish the dispensing vessel with material. In this way, the injection of material into the process can be continually maintained.

Applications of Pneumatic Injection

- Granular Coal Injection

- Pulverized Coal Injection

- Wood Pellet Injection

- Oxy-Fuel Burners

- EAF Carbon and Lime Injection

Downloads

Data sheets

Specials / Studies

Brochures

We’re there for you

Partnership for us means always being on hand to support you whenever and wherever you need us. With our global network of locations and expert partners, we make sure we are always right by your side.