Our global services revolve around your needs

When it comes to keeping your business running to optimum, our global service team is there for you – digitally or on-site – whenever, wherever, and with whatever it takes. Our job begins from the moment you receive your new machine or system and never stops. We are ‘always-on’ and at your service with the tailored support and spare parts you need for the entire lifecycle of your process solutions.

We are wherever you need us to be

With 24/7 & 365 support

So we can immediately respond to your needs, our global service team is always available.

With > 100 technicians

For expert support on the ground, our global network of technicians always has you covered.

With > 30 service bases

No matter where you need us to be, we are always close by with the expert local support you need.

Our services revolve around your needs

For the entire life cycle of your process solutions

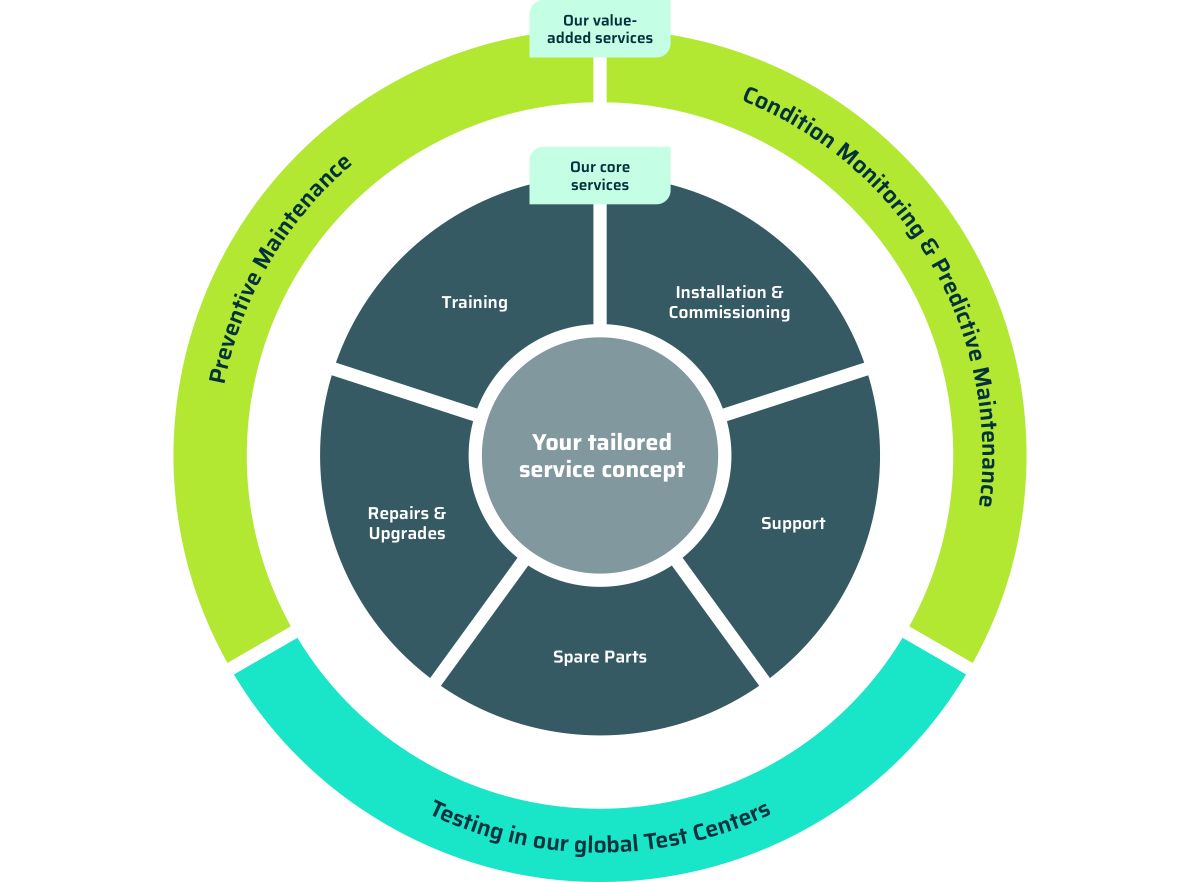

Because the challenge of maximizing your uptime and keeping your systems running to optimum is unique, we work with you to develop and implement a concept that is fully tailored to your unique needs – from consultancy and core services to testing and next-level digital solutions.

Bringing your tailored service concept to life

Creating a unique service concept that will meet your unique needs begins with an expert analysis of your current systems and processes. With our consultancy and Fitness Checks we help you clearly identify the key issues – and the best way forward.

Installation

Safe and efficient installation is significant to deliver a faster ROI. Our installation experts can take on complete mechanical and electrical installation services or provide remote guidance and support for your contractors.

Support & Consulting

Faster problem resolution is the key to maximizing your uptime. With our real-time Expert Remote Support solution CONiQ Assist we help you resolve issues faster – reducing your downtime and the need for more costly on-site visits.

Repairs, Spares & Upgrade

Proactive information and short waiting times are necessary to ensure maximum on-site availability. We help you to avoid downtime through early detection of failures. We work with you to define the best solution: whether it’s a Refurbishment at our workshop or a Repair at your site with original spare parts. Extend your asset lifecycle with an Upgrade and get access to latest functionality.

Training

Transfer of expert system know-how and real hands-on experience enables optimum operation and maintenance. We support your teams with the tailored Training they need to take control of your in-house servicing. Online, at your site or at one of our offices.

Monitoring & Prevention

Smart systemic data is crucial to deliver a truly next-level service concept. Our digital monitoring solutions such as CONiQ Cloud keep your finger on the pulse of your system’s health. We are laying the foundations for a networked service that will give you the real-time data to proactively maximize your uptime in future.

Testing

Making sure your materials and machines are perfectly matched is fundamental to minimize the need for service. Our global Test Centers give you the results you can count on to deploy new solutions with absolute confidence.

Cloud

Explore your digital transformation with us

Discover the innovative products and stories behind Schenck Process NEXT and our digitalization strategy.

Our testing makes a world of difference

If you want complete peace of mind that your materials and machines are perfectly matched – our global Test Centers are always up to the challenge.

All the product support you need

Looking for a software update? Need a configuration or a new product manual? Just click on the link below.

Can you make processes work?

We are always looking for people who share our passion for solving complex challenges. And we have rewarding career opportunities to match every ambition. It doesn't matter what gender you identify with, what you believe in, who you love, where you come from or what color your skin is: it’s our passion for what we do that unites us.

We’re there for you

Partnership for us means always being on hand to support you whenever and wherever you need us. With our global network of locations and expert partners, we make sure we are always right by your side.

Privacy settings

We use cookies to optimize our website’s functionality and continuously improve your experience.

Some types of cookies are essential to the technical functionality of our website.

Additional cookies are used only with your consent. In this context, we use Google Analytics in the anonymized version to access, analyze, and save information, such as the characteristics of your device and certain personal data (IP addresses, navigation usage, geolocation data, or unique identification features. (YouTube, FB, etc.))

With regard to the processing of your data in the USA by Google: By clicking on [“Agree to all”], you also consent to the processing of your data in the USA in accordance with Article 49 (1) (a) of the GDPR. According to the European Court of Justice’s current case law, the USA is assessed as a country with an inadequate level of data protection by EU standards. In particular, there is a risk that your data could be processed by US authorities without you becoming aware of it or having access to legal remedy. If you click on [“Save preferences”] without having selected “Analytics”, the transfer of data described above will not take place. Further information can be found in our data protection information.